Services

Instrumentation, Electrical & Mechanical Jobs

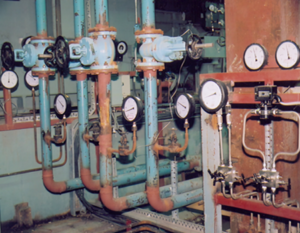

CHEMIN C & I draw upon its diverse industry experience to engineer the complete turnkey solutions for process industry from design, detailed engineering, drawing, documentation, procurement, supply to installation and commissioning, and we provide complete solutions under one roof in the field of Instrumentation, Electrical and Mechanical .

Four Decades of proven experience in Electrical, Instrumentation Process Control Systems and Plant Illumination serving at various Power Plants, Sugar Plants, Paper, Cement, Steel Plant, Refinery Petro-Chemical, Water treatment, CGP Co-gen, various Chemical Plants, etc., in Government, Private Sectors & Overseas customers.

43 Years of Glorious Service to the Nation – Successfully more than 500 projects I Having more than 1000 direct and indirect manpower I Quality I Safety I Commitment.

CHEMIN C & I shall adhere to safe construction practice and guard against hazardous and unsafe working conditions and shall comply with OWNER’S safety rules as set forth.

To achieve the intended outcomes, including enhancing the organization’s environmental & Health & Safety performance, we shall establish, implement, maintain and continually improve an environmental management system & Occupational Health & Safety Systems, including the processes

needed and their interactions, in accordance with the requirements of ISO 14001:2015 & ISO 45001:2018 standards.